On-Demand Solutions

Because we can do more than just print

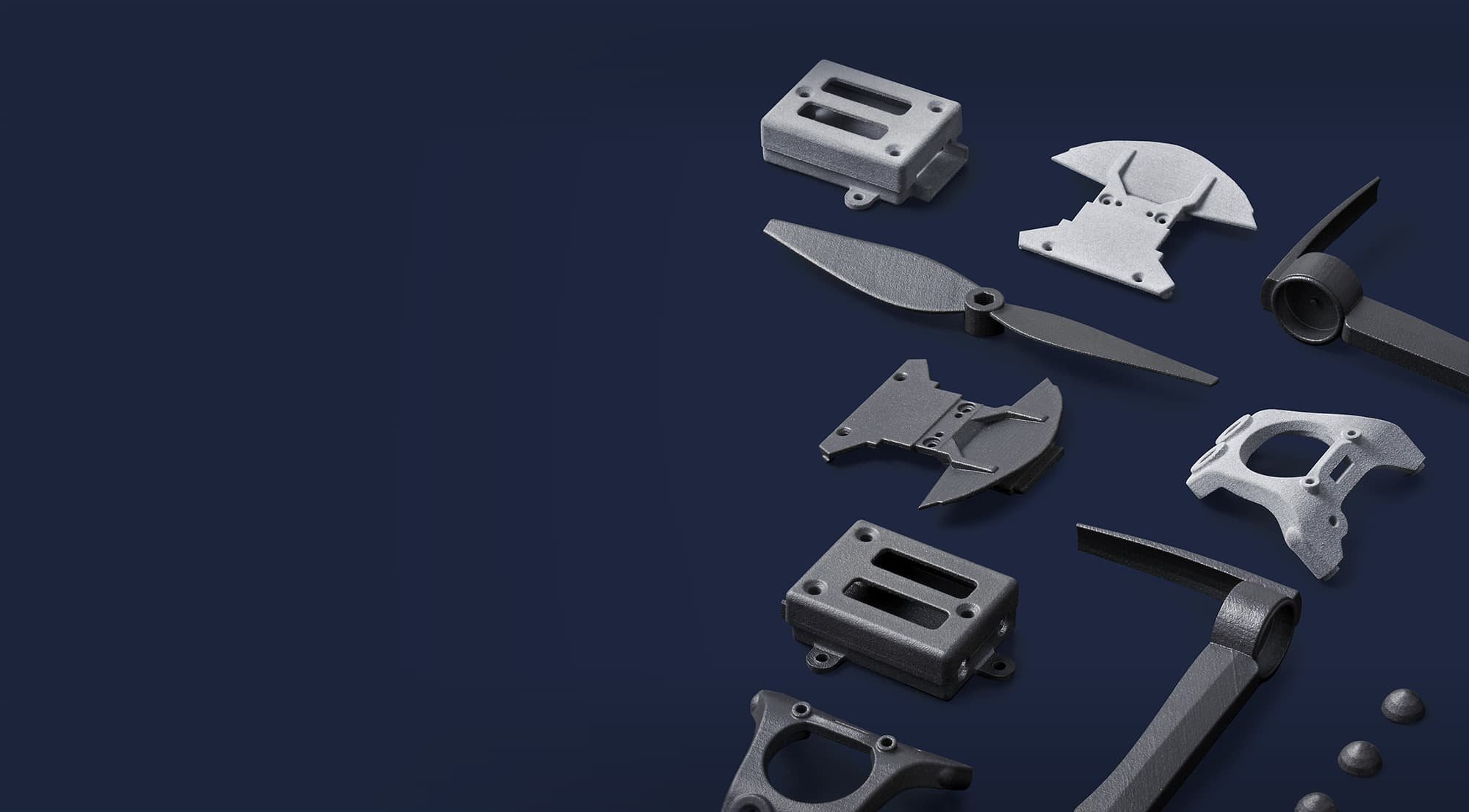

Building your digital inventory with confidence, one part at a time

With Part Validation, we ensure your design works exactly as intended before it enters digital inventory. So when you need the On-demand, you know the work.

Additive manufacturing involves many variables so we offer part validation for making sure the parts work as intended

Part Validation

Test. Prove. Perfect. Before it matters.

Digital Inventory

Your parts, always on the shelf - digitally.

Once your parts are validated, they can be stored securely in your Digital Inventory. Your online shelf of production-ready parts.

Reordering takes seconds:

no warehouse

no minimum order quantity

no six-month lead times.

That’s the new standard for agility: minimal stock, maximal flexibility.

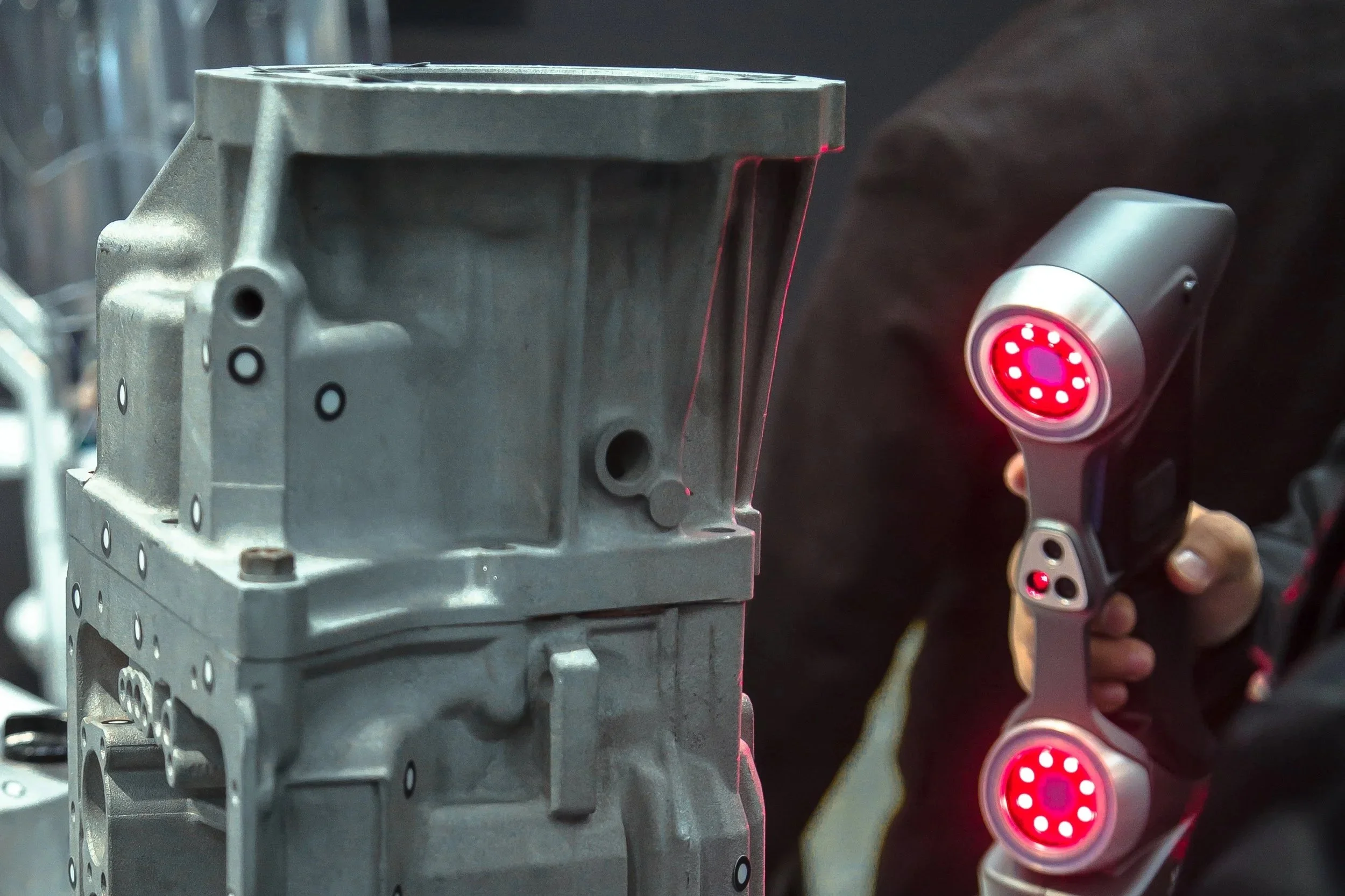

Many critical components still exist only as physical parts. With Reverse Engineering, we bridge that gap.

We scan your part, rebuild it as a precise 3D model, and then validate it for additive manufacturing. Once approved, it joins your digital inventory as an on-demand spare part

Reverse Engineering

Bring legacy parts into the digital age.

Frequently Asked Questions

How does part validation work and why is it needed?

Which types of parts can be reproduced through reverse engineering?

Are there any limitations when creating reverse engineered components from an existing part?

Why Choose Norra AM?

-

Easy

From the moment you contact us, our streamlined processes and instant quoting system make ordering prototypes straightforward and hassle-free. We simplify the complex, so you can focus on innovation.

-

Fast

Our state-of-the-art manufacturing technology allows us to produce high-quality prototypes with rapid turnaround times. Whether you need a single prototype or a large batch, we deliver your parts quickly to keep your projects on track.

-

Local

Based in Hudiksvall, we provide personalized support and fast delivery times. Being local means we understand your needs better and can offer timely assistance and services, ensuring your prototypes meet your exact specifications.