SLS vs MJF

Which 3D Printing Technology Should You Choose?

Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF)

two of the most capable powder-based 3D printing technologies used for functional prototypes and end-use parts.

When comparing SLS vs MJF, both often rely on similar materials, primarily PA12 nylon and related variants, but the way each technology handles these materials results in distinct differences.

In mechanical performance, the MJF vs SLS strength comparison typically shows MJF producing slightly stronger and more isotropic parts, while SLS tends to deliver cleaner edges and more uniform cosmetic detail.

.

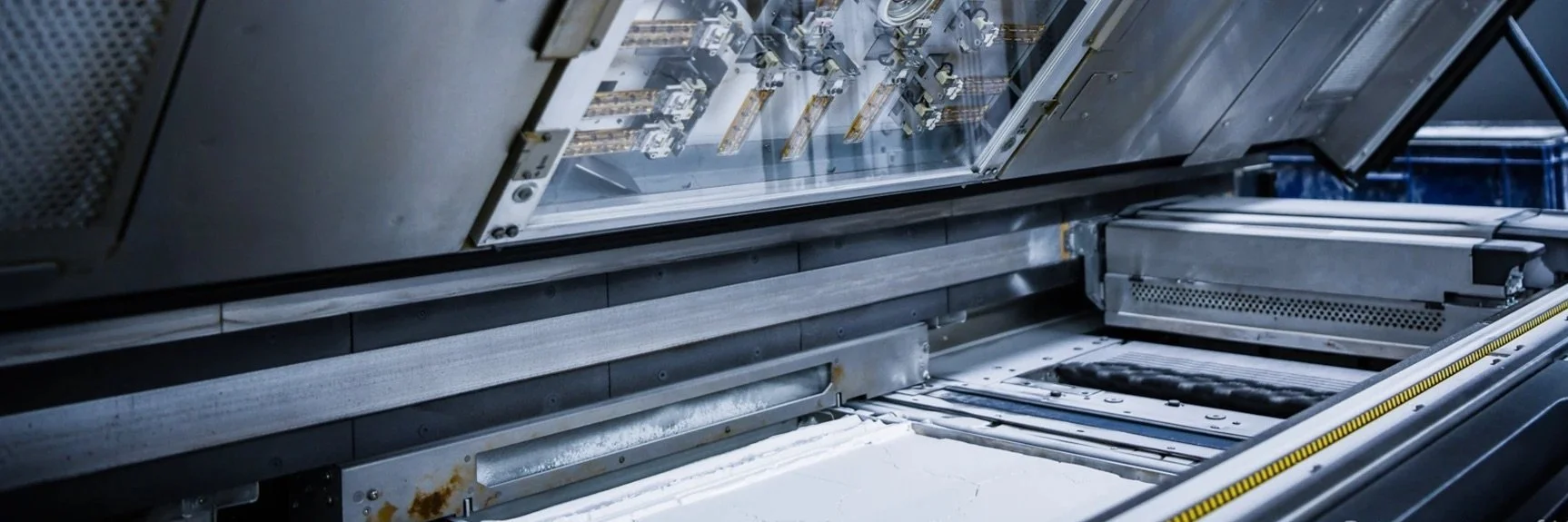

Multi Jet Fusion (MJF)

MJF typically delivers more isotropic properties and is a strong choice for functional, load-bearing parts where mechanical performance matters. Standard color is gray, and parts are often denser straight out of the machine, which helps with water-/air-tightness for things like enclosures.

In production, MJF is also more predictable for capacity planning because build time depends more on overall build volume than geometry, although on large flat surfaces you can sometimes see a slight capillarity effect if the surface isn’t angled.

Selective Laser Sintering (SLS)

SLS is normally white as standard and can be slightly more porous, so if you need fully air-tight parts (for example vacuum applications), vapor smoothing can be especially relevant.

SLS can also show weaker properties in the Z-direction compared to XY, but it excels in detail definition and edge sharpness, making it great for crisp geometry, assemblies, and intricate parts where surface detail and cosmetic features matter.

In short, choose MJF for durability, strength, and production-ready performance, and choose SLS for precision, cosmetic detail, and design-driven components. Both processes are highly capable, but the best choice depends on part requirements, complexity, and intended use.

Make sure to also visit Understanding Material Differences in Additive Manufacturing

What is the main difference between SLS vs MJF for functional 3D printed parts?

When does the MJF vs SLS strength comparison matter most?

When should I choose SLS instead of MJF for my 3D printed parts?

Frequently Asked Questions

Why Choose Norra AM?

-

Easy

From the moment you contact us, our streamlined processes and instant quoting system make ordering prototypes straightforward and hassle-free. We simplify the complex, so you can focus on innovation.

-

Fast

Our state-of-the-art manufacturing technology allows us to produce high-quality prototypes with rapid turnaround times. Whether you need a single prototype or a large batch, we deliver your parts quickly to keep your projects on track.

-

Local

Based in Hudiksvall, we provide personalized support and fast delivery times. Being local means we understand your needs better and can offer timely assistance and services, ensuring your prototypes meet your exact specifications.