STL vs STEP

Choosing the Right File Format for Additive Manufacturing

When comparing file formats for additive manufacturing, the choice usually comes down to STL vs STEP because they support different stages of the workflow.

.STEP (or .stp)

Step preserves real CAD data (solid bodies, surfaces, tolerances, and design intent), so it’s ideal during design and engineering, especially when parts need modification, inspection, or tight control.

.STL

STL is still the standard for actual 3D printing in polymer additive manufacturing. It stores the model as a triangle mesh that slicers process reliably across printers and materials. 3MF is also widely available in software menus and is increasingly supported, but many workflows still export STL for print-ready files.

STL vs 3MF

Searches like “STL vs 3MF” or “STL or 3MF for 3D printing” are common. 3MF supports color, textures, and metadata, but for engineering-grade nylon and functional parts it’s mainly about clean geometry and predictable slicing, most workflows use STL.

Best Practise

Use STEP for design, revision, and engineering—especially if you don’t want to mess with resolution. When the part is ready for additive manufacturing, export 3MF when supported, and use STL for maximum compatibility.

Frequently Asked Questions

What is the main difference between STL and STEP for 3D printing?

Why should I send a STEP file when requesting design checks or adjustments?

Should I use STL or STEP when preparing parts for additive manufacturing?

Why Choose Norra AM?

-

Easy

From the moment you contact us, our streamlined processes and instant quoting system make ordering prototypes straightforward and hassle-free. We simplify the complex, so you can focus on innovation.

-

Fast

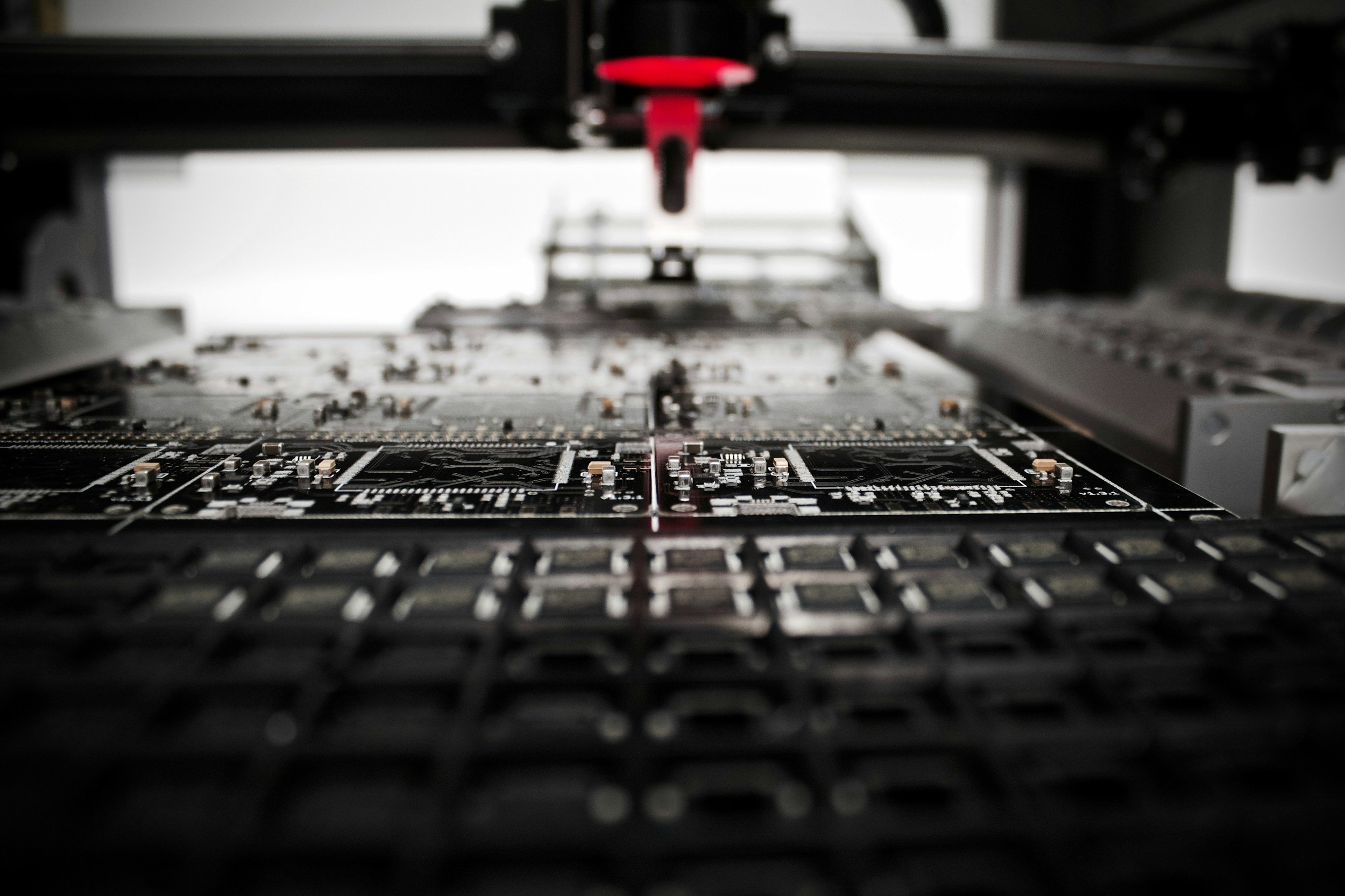

Our state-of-the-art manufacturing technology allows us to produce high-quality prototypes with rapid turnaround times. Whether you need a single prototype or a large batch, we deliver your parts quickly to keep your projects on track.

-

Local

Based in Hudiksvall, we provide personalized support and fast delivery times. Being local means we understand your needs better and can offer timely assistance and services, ensuring your prototypes meet your exact specifications.