Understanding Cost

How Much Does 3D Printing Cost

Understanding the main cost drivers makes it easier to estimate what affects the price and how to optimize it.

Key factors that shape 3D printing cost:

Part size & volume:

Larger parts use more material and take longer; small parts can still cost more if packing is inefficient or waste inside the build volume is high.

Surface treatments:

Raw parts are cheapest; dyeing, vapor smoothing, polishing, or coating add labor and time.

Lead time & quantity:

Standard lead time is cheapest; rush costs more; higher quantity often lowers cost per unit through efficient nesting and shared machine time.

Geometry & complexity:

Solid blocks, very fine details, thin unsupported walls, or shapes that reduce packing density can increase print time (especially in SLS) and material use.

Material choice:

PLA, PETG (most affordable) → PA12, PA11, PA-CF (higher strength/accuracy, higher cost) → PEEK, PEKK (advanced processing, highest price).

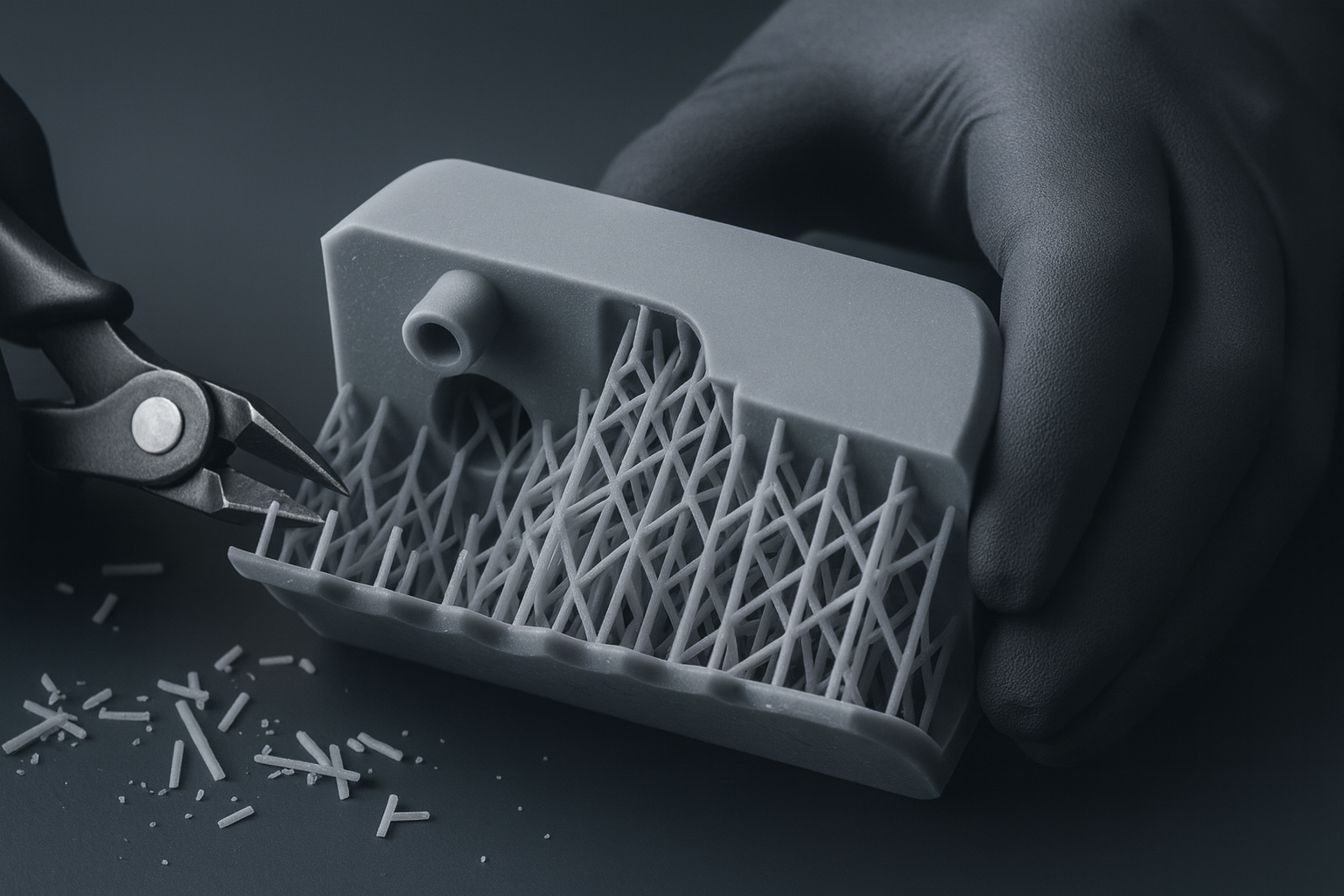

Manual labor & secondary ops:

Heated inserts, extra powder removal/cleaning steps, post-processing handling, or manual support removal in FDM add cost fast.

3D printing cost varies depending on what you make, the material, and how the part will be used. Instead of a fixed price, 3D printing is typically calculated from material consumed, the space the part occupies in the build, and finishing requirements.

How much does 3D printing cost for different types of parts?

Why can the price vary so much, and is 3D printing expensive?

What can I do to reduce the 3D printing cost of my part?

Frequently Asked Questions

Why Choose Norra AM?

-

Easy

From the moment you contact us, our streamlined processes and instant quoting system make ordering prototypes straightforward and hassle-free. We simplify the complex, so you can focus on innovation.

-

Fast

Our state-of-the-art manufacturing technology allows us to produce high-quality prototypes with rapid turnaround times. Whether you need a single prototype or a large batch, we deliver your parts quickly to keep your projects on track.

-

Local

Based in Hudiksvall, we provide personalized support and fast delivery times. Being local means we understand your needs better and can offer timely assistance and services, ensuring your prototypes meet your exact specifications.