Material Comparison

Understanding Material Differences in Additive Manufacturing

Choosing the right material is one of the most important steps in additive manufacturing. Each material family offers different levels of strength, durability, heat resistance and surface quality and these differences directly affect performance, appearance and cost. Whether you’re comparing standard polymers, engineering-grade nylons or high-performance materials, understanding the basics makes it easier to select the right option for your application. This simple overview helps clarify how materials behave and what to expect from them in real-world use.

Crystallinity (Semi-crystalline vs Amorphous)

In additive manufacturing, crystallinity affects strength, heat behavior, chemical resistance, and processing.

Semi-crystalline polymers

High mechanical strength

Excellent chemical resistance

Good thermal stability

Best for load-bearing parts and solvent/heat-exposed components

Amorphous polymers

Dimensional stability

Optical clarity (often)

Easier machining and thermoforming

Best for housings, transparent parts, and fine-feature components

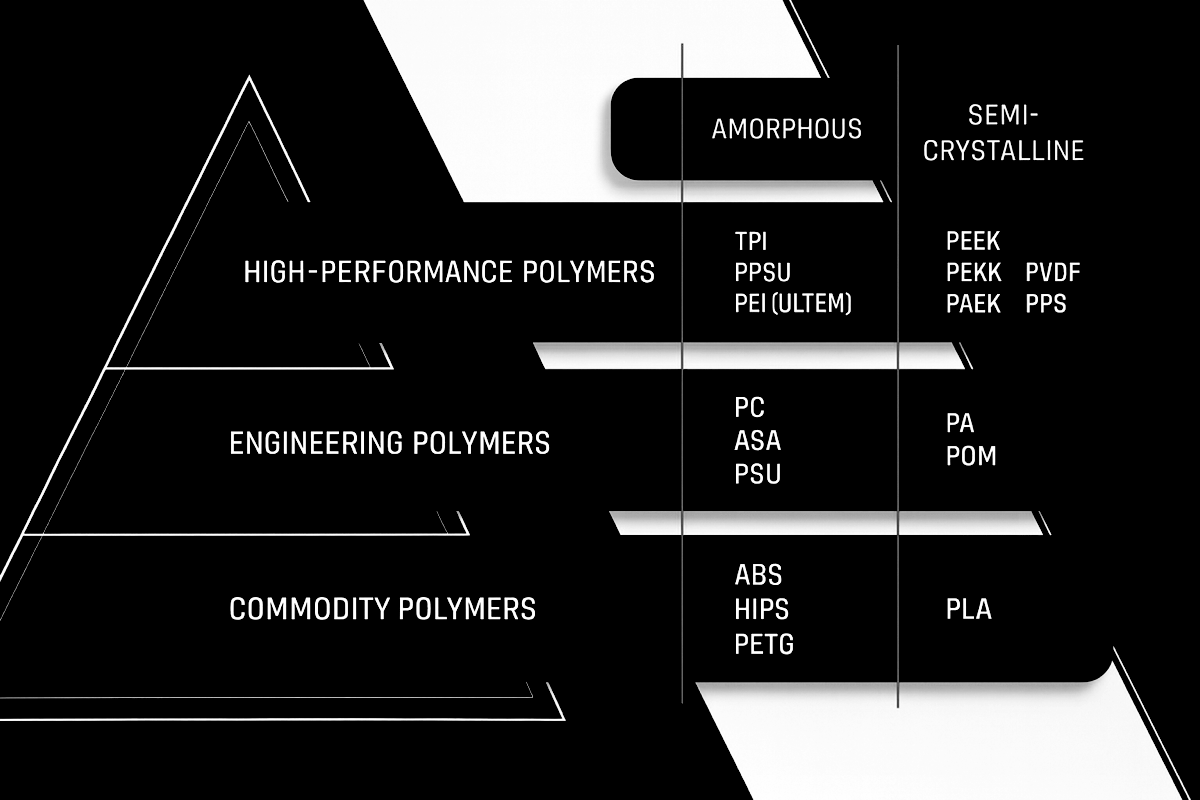

The Polymer Pyramid groups plastics by performance vs cost—useful when choosing materials for additive manufacturing (AM):

Commodity polymers: low cost, general-purpose plastics for simple prototypes and non-critical parts (e.g., PP, PS, PE).

Engineering polymers: stronger and more stable for functional AM parts, housings, and fixtures (e.g., PC, PA, POM).

High-performance polymers: for extreme heat/chemicals and demanding applications, typically higher cost and harder to process (e.g., PEEK, PTFE, PI).

Make sure to also visit Choosing Material & Technology

How do material choices like PLA vs PETG or PA11 vs PA12 affect 3D printing cost?

Is 3D printing expensive if I need strong or functional parts?

What is the most cost-efficient way to choose between PLA vs PETG or PA11 vs PA12?

Frequently Asked Questions

Why Choose Norra AM?

-

Easy

From the moment you contact us, our streamlined processes and instant quoting system make ordering prototypes straightforward and hassle-free. We simplify the complex, so you can focus on innovation.

-

Fast

Our state-of-the-art manufacturing technology allows us to produce high-quality prototypes with rapid turnaround times. Whether you need a single prototype or a large batch, we deliver your parts quickly to keep your projects on track.

-

Local

Based in Hudiksvall, we provide personalized support and fast delivery times. Being local means we understand your needs better and can offer timely assistance and services, ensuring your prototypes meet your exact specifications.