Materials & Technology

Choose the right Material for your application

Our Base Materials

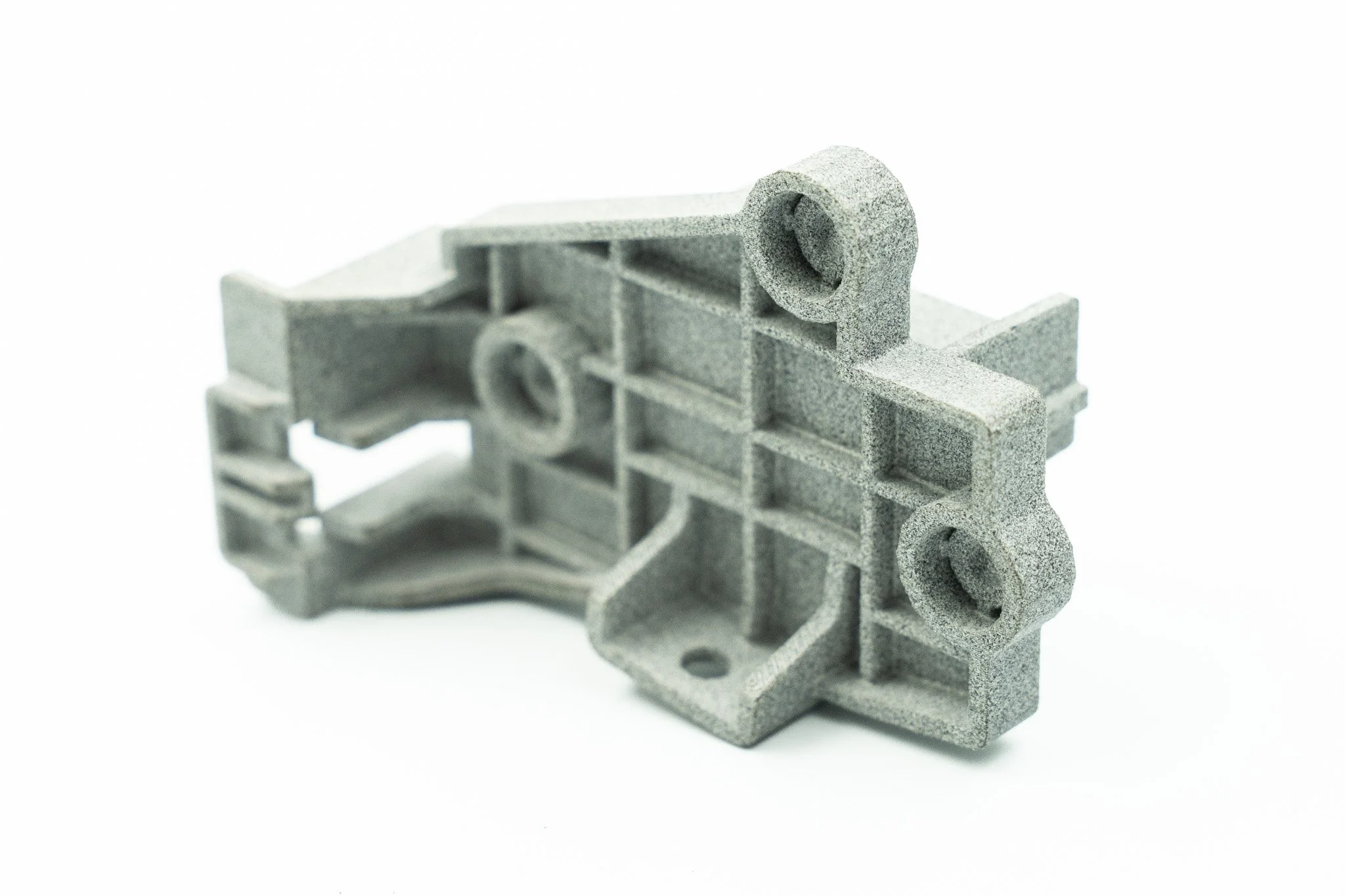

Gray Nylon Parts

MJF - PA12

Versatile and suitable for strong and precise production parts

White Nylon Parts

SLS - PA12

White nylon with sharp detail and accuracy

Additional Materials

Reinforced Nylon Parts

SLS - PA12GF

Rigid, dimensionally stable, low-warp tooling and fixtures

ESD Nylon Parts

MJF - PA12

Static-dissipative, strong, and accurate for electronic applications

Flexible Parts

SLS - TPU

Elastic, durable, and resilient for functional applications

Special Materials & Applications

From food-safe and high-temperature polymers.

Contact us to discuss special materials

How do I know which material is best suited for my specific application?

You choose 3D printing material based on strength, flexibility, heat resistance, and surface finish. We guide you through selecting the strongest 3D printing materials or flexible vs rigid options depending on your needs.

What is the difference between MJF and SLS when choosing a material?

The technologies offer different trade-offs—MJF produces stronger, more isotropic parts, while SLS gives cleaner surface detail. When comparing materials like PA11 vs PA12, the choice depends on whether you need impact resistance or maximum stiffness.

Are there any limitations or design considerations I should be aware of when choosing a material?

Yes, each material has minimum wall thickness, gap, and feature size limits. These vary between the strongest 3D printing materials and flexible vs rigid materials, so always cross-check with our Design Guidelines.